3D-printed smart CLs?

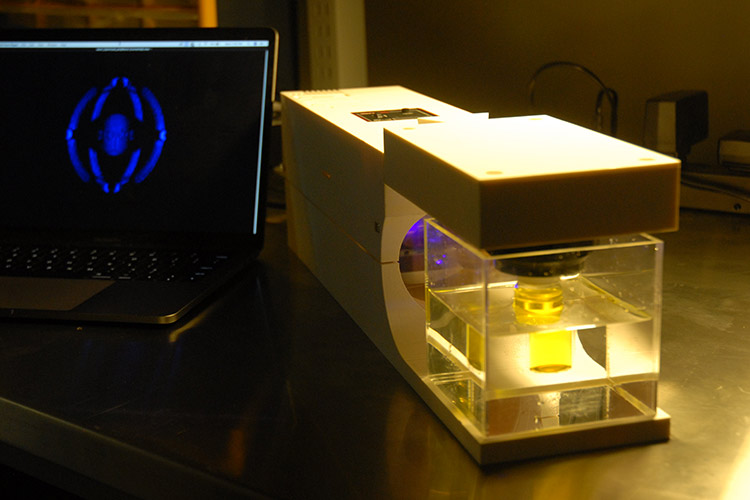

Researchers at the University of California, Berkeley, have developed a new 3D printer they say could print clear, soft hydrogels around tiny electronic circuits to make smart contact lenses.

The printer, which projects rays of light into a gel to harden it in the desired shape in minutes, overcomes some of the drawbacks of traditional 3D printing, which lays material down layer by layer to create a model, researchers told The Guardian.

Nicknamed the “replicator” by the inventors — after the Star Trek device that can materialise any object on demand — the 3D printer can create objects that are smoother, more flexible and more complex than what is possible with traditional 3D printers. It can also encase an already existing object with new materials — for instance, adding a handle to a metal screwdriver shaft — which current printers struggle to do.

The technology has the potential to transform how products from prosthetics to eyeglass lenses are designed and manufactured, said Hayden Taylor, assistant professor of mechanical engineering at UC Berkeley. “I think this is a route to being able to mass-customise objects even more, whether they are prosthetics or running shoes.”

Building objects layer by layer leads to a “stair-step” effect along the edges, he said, adding that traditional 3D printers also have difficulty creating flexible objects because bendable materials could deform during the printing process and supports are required to print objects of certain shapes, like arches.

The new printer relies on a viscous liquid that reacts to form a solid when exposed to a certain threshold of light. Projecting carefully crafted patterns of light — essentially “movies” — onto a rotating cylinder of liquid solidifies the desired shape “all at once.”

The new printer was inspired by the computed tomography (CT) scans that can help locate tumours and fractures within the body. “Essentially we reversed that principle,” Taylor said. “We are trying to create an object rather than measure an object, but actually a lot of the underlying theory that enables us to do this can be translated from the theory that underlies computed tomography.”

Besides patterning the light, which requires complex calculations to get the exact shapes and intensities right, the other major challenge faced by the researchers was how to formulate a material that stays liquid when exposed to a little bit of light, but reacts to form a solid when exposed to a lot of light.

“The liquid that you don’t want to cure is certainly having rays of light pass through it, so there needs to be a threshold of light exposure for this transition from liquid to solid,” Taylor said.

The 3D printing resin is composed of liquid polymers mixed with photosensitive molecules and dissolved oxygen. Light activates the photosensitive compound which depletes the oxygen. Only in those 3D regions where all the oxygen has been used up do the polymers form the “cross-links” that transform the resin from a liquid to a solid. Unused resin can be recycled by heating it up in an oxygen atmosphere, he explained.

The technique also generates almost no material waste and the uncured material is 100% reusable. Objects also don’t have to be transparent, with the researchers printing objects that appear opaque using a dye that transmits light at the curing wavelength but absorbs most other wavelengths.